The Perfect Positive Mould for Prosthetics

5 tips and tricks to create a positive mould

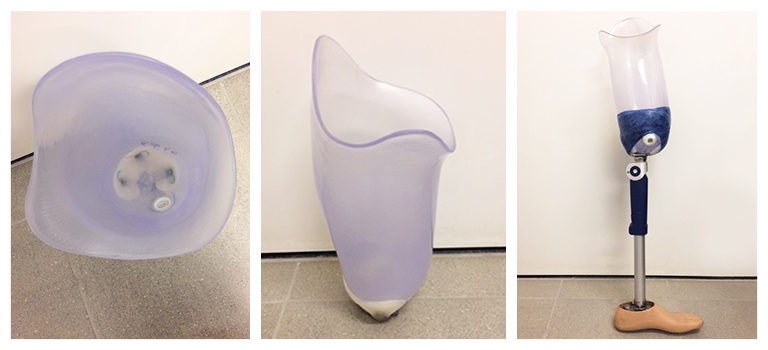

The positive mould forms the base of every prosthetic check socket or liner. It can be made from plaster or foam, but in general, both materials are shaped and adjusted in a very similar way.

If you consider the following tips and tricks when making and positioning a positive mould, you will reach the best results for your final socket. An added benefit of this method is that you will not have to use a tricot cover.

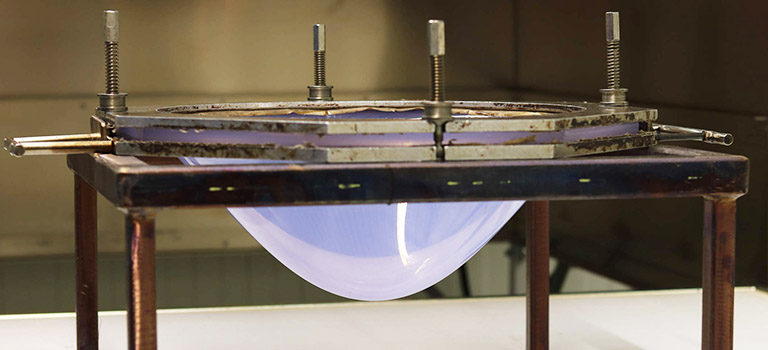

Tip 1: Perfect positioning of the positive mould

Position the positive mould on a round pipe or metal rod that is vertically aligned.

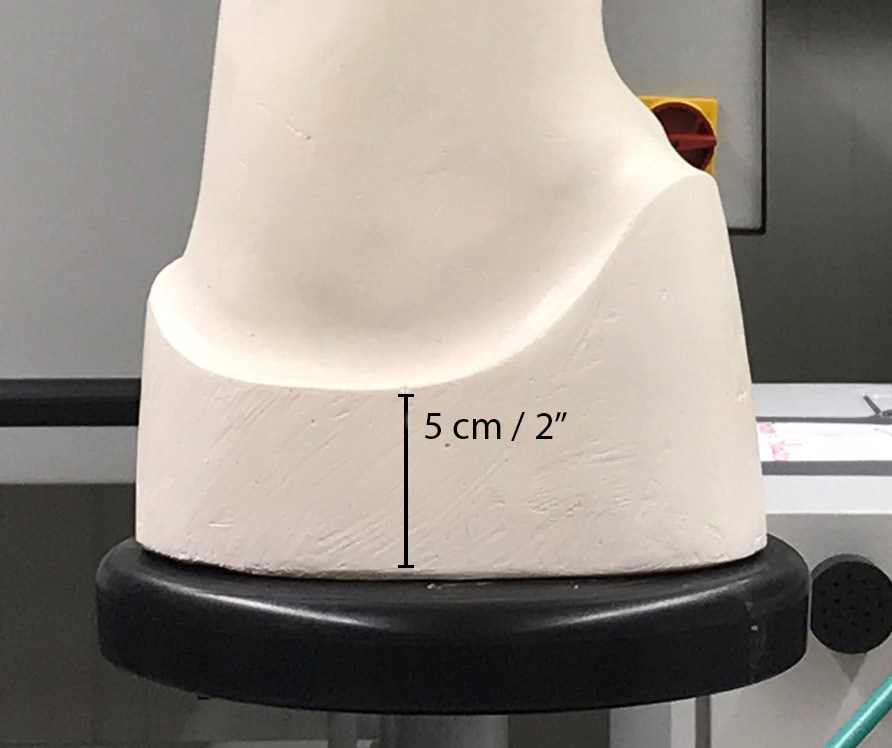

Make sure to give the positive mould a broad and conical base. A good foundation will make it easier to form and remove the final socket.

The edge of the positive mould should be longer than the proximal edge of the final socket. This will allow you to easily mould the edges of the socket. The proximal edge should be about 5 cm (2″) long.

Tip 2: Smooth positive mould for perfect sockets

The plaster or foam model must have a smooth surface if you want the socket to be smooth on the inside. Be aware that all imperfections on the mould will be transferred to the check socket.

Polish and buff the plaster mould to obtain an even surface. You can use regular and waterproof sandpaper with a P1000 to P1500 grit.

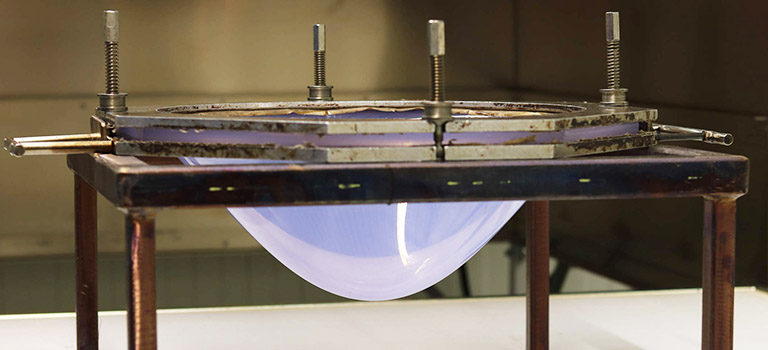

Tip 3: Optimal vacuum suction

Carve air extraction ducts in the plaster underneath the proximal borders of the socket. This allows the air to escape so that the vacuum suction can do its work.

Tip 4: Avoid water

Keep in mind that water is enemy number one of high-temperature thermoplastic sheet materials. If water comes in contact with the thermoplastic, the final socket will have an uneven, milky surface and air bubbles. Take this into account when making a plaster positive mould.

Tip: This issue does not occur with foam positive moulds.

To prevent water from interacting with the high-temperature thermoplastic, you can isolate the plaster mould with an acrylic varnish.

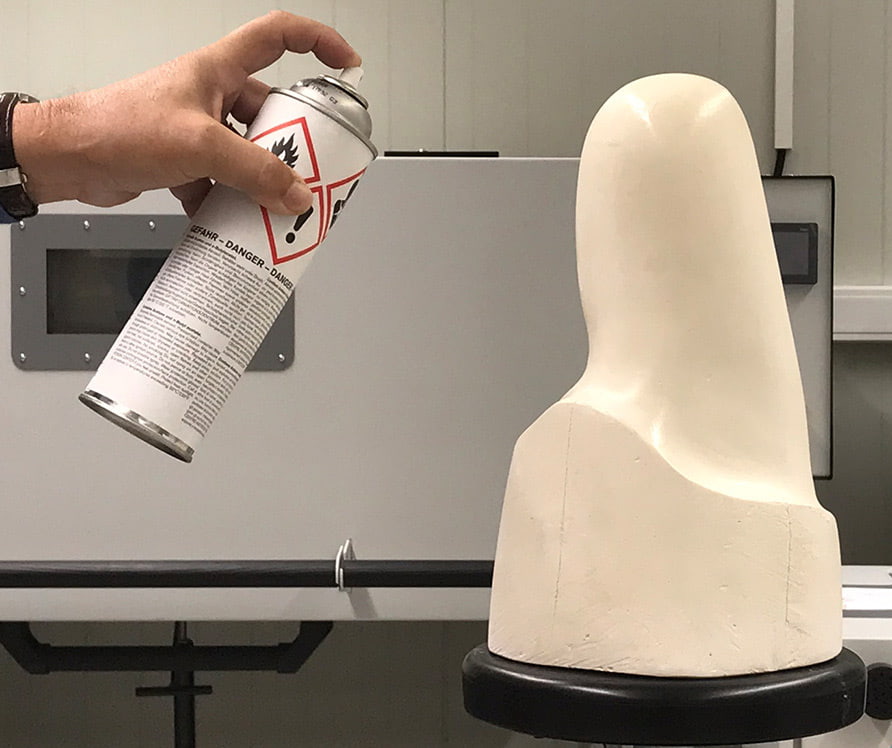

Tip 5: Easy socket removal

As a final step to prepare your positive mould before forming the socket, you can apply a light layer of silicone de-moulding spray.

This silicone layer will ensure that the thermoplastic material does not stick to the positive mould during application and that it will easily come off once it has cooled down.

Once you have created the perfect positive mould, you can get started with the fabrication of the prosthetic socket or liner. Continue reading our top tips for bubble-forming and drape-forming a thermoplastic check socket or liner.

![]()

Written by Marc Blij

Marc studied in Brussels and London and is a Certified Orthotist and Prosthetist.

After working in an O&P lab at the Universities of Louvain and Brussels, he decided to set up his own O&P lab in Antwerp. For over 30 years, he ran his practice together with his wife.

Since 2006, Marc works at the Orfit Industries headquarters in Wijnegem (Belgium) as a Product and Educational Specialist in Orthotics & Prosthetics and Physical Rehabilitation.

![]()